How intelligent fire detection, predictive analytics, and wireless monitoring are becoming the operational backbone for India’s mega-warehouses safeguarding supply chains, protecting assets, and ensuring on-time delivery at scale.

In October 2024, a devastating fire engulfed the V Logistics warehouse in Bhiwandi, Maharashtra — one of India’s busiest freight corridors near the Mumbai–Nashik Highway. The blaze, which stored hydraulic oil, textiles, plastics, and chemicals, completely destroyed the facility. Six fire tenders from three different municipalities were needed just to fight the flames. The warehouse was reduced to ash — and with it, the inventory, the timelines, and for the brands that depended on it, a significant chunk of revenue.

Then, just weeks later, a fire at a Shiprocket fulfillment warehouse destroyed goods belonging to over 60 brands — including household names like Sugar and mCaffeine — worth several hundred crores. The incident did not just cause property damage; it disrupted supply chains across the board, raising urgent questions about how India’s rapidly expanding warehousing sector is protecting its most critical assets.

These are not isolated incidents. They are symptoms of a structural gap: India’s warehousing industry is growing at a breakneck pace, but fire safety systems in many facilities remain stuck in an earlier era of detection. The solution is not simply more extinguishers or wider aisles. It is intelligent, connected, predictive fire safety — powered by AIoT.

A single warehouse fire can cost not just the building, but the company’s credibility, its supply chain, and its future.

Warehouses are not like offices or malls. They are high fire-load environments sprawling, often exceeding 100,000 sq. ft., storing diverse materials from electronics to chemicals, and frequently operating with skeleton crews during off-peak hours. This combination creates conditions where fires ignite fast, spread faster, and are detected far too late.

India’s warehousing market reached approximately USD 60.42 billion in 2024 and is projected to grow at a CAGR of 10.5% through 2034, reaching nearly USD 164 billion. Warehousing space expanded by 12% in 2024 alone, with Mumbai leading at 10.3 million sq. ft. of new capacity. Manufacturing accounted for 48% of warehouse uptake in early 2025, while e-commerce surged 151% year-on-year.

Government initiatives like PM Gati Shakti and Make in India are accelerating infrastructure development, with private equity capturing 66% of H1 2024 inflows in industrial and warehousing. GST consolidation has shifted storage from fragmented godowns to large, centralised Grade-A facilities — but larger does not automatically mean safer.

Equipment malfunction accounts for 44% of warehouse fires, while electrical distribution is responsible for 19% of incidents. In India’s climate — with temperatures routinely exceeding 40°C and humidity reaching 90% — electrical systems and stored materials face accelerated degradation. Traditional fire detection systems, many of which rely on imported sensors originally designed for temperate climates, often fail precisely when they are needed most.

The National Building Code of India (NBC 2016, Part 4) mandates automatic fire detection and alarm systems for warehouses based on occupancy classification and building height. Yet compliance alone does not guarantee effectiveness. A system that detects fire after flames are visible is already too late in a high-density storage environment.

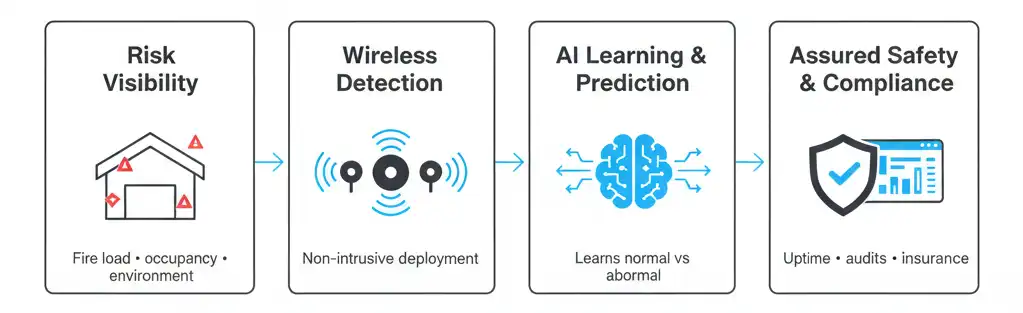

Traditional fire alarm systems operate on a simple principle: detect smoke or heat, trigger an alert. This reactive model worked well when warehouses were small, inventory was limited, and response times were measured in minutes. Today’s mega-warehouses demand something fundamentally different — a system that does not just react to fire, but anticipates it.

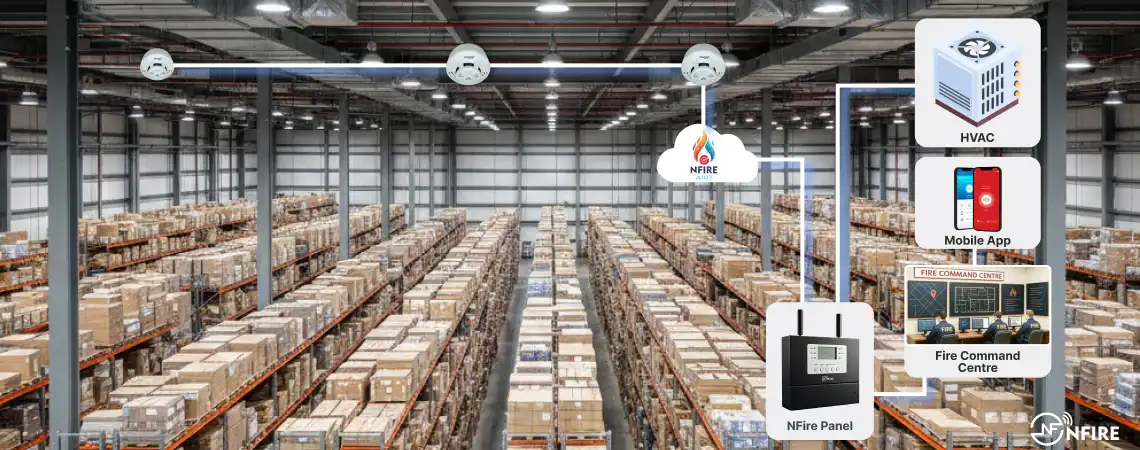

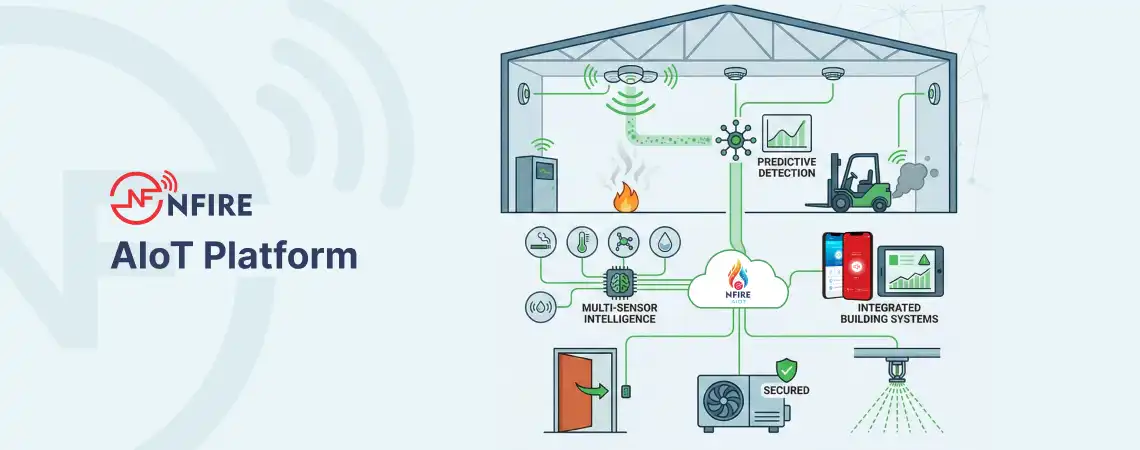

AIoT — Artificial Intelligence combined with the Internet of Things — makes this possible. By deploying a distributed network of wireless addressable sensors across a warehouse, and feeding their continuous data streams into a cloud-based AI engine, modern fire safety platforms can detect the earliest invisible signatures of a developing fire — temperature gradients, particulate patterns, gas concentrations, and humidity anomalies — long before smoke becomes visible or flames ignite.

An AIoT fire safety platform for warehouses operates across three integrated layers:

NFire, developed by Atigo Corporation, represents India’s flagship AIoT-based wireless addressable fire alarm system — EN54 and IS/ISO 7240 certified, purpose-engineered for India’s climate and built from the ground up with warehouses, logistics parks, and critical infrastructure in mind.

| Capability | What It Delivers for Warehouses |

|---|---|

| Wireless Addressable Detection | Pinpoint-accurate fire location across sprawling warehouse zones — no blind spots, no ambiguous zone alerts. |

| AI-Driven Predictive Analytics | Detects pre-fire anomalies — temperature spikes, gas buildup, particulate drift — before smoke or flames appear, enabling intervention minutes earlier. |

| False Alarm Suppression | ML models learn the warehouse’s operational baseline, filtering out dust, steam, and equipment heat — reducing nuisance alarms by over 90%. |

| 24/7 Emergency Monitoring | Round-the-clock monitoring with direct escalation to emergency services — modelled on the US 911 response process, operational since 2013. |

| BMS & WMS Integration | Open APIs connect NFire seamlessly with Building Management Systems and Warehouse Management Systems — coordinating HVAC, doors, and suppression during incidents. |

| Predictive Maintenance | Continuous health and battery monitoring of every sensor with proactive alerts before degradation — preventing silent detection gaps. |

| Mobile & Web Dashboards | NFire Connect app and web portal deliver real-time alerts, zone maps, incident logs, and compliance reports — accessible from anywhere. |

| Built for India’s Conditions | Designed to operate reliably in high heat, dust-heavy, and power-variable environments common across Indian warehouse operations. |

Unlike imported systems that degrade in extreme heat and humidity, NFire was engineered from the outset to operate reliably in India’s environment. R&D that began in 2009 specifically addressed the failure of foreign sensors in 40°C+ heat and 90% humidity — conditions that are routine across India’s logistics corridors from Bhiwandi to Bengaluru.

For logistics and e-commerce companies, a warehouse fire is not simply a property loss event. It is a supply chain disruption event with cascading consequences.

Predictive fire safety systems shift the equation from “minimise damage after ignition” to “prevent ignition altogether”. For warehouse operators managing multi-client inventory across logistics parks, this is no longer a safety upgrade — it is a business continuity requirement.

India’s National Building Code (NBC 2016, Part 4) classifies warehouses and storage facilities under specific occupancy groups and mandates automatic fire detection and alarm coverage based on building dimensions and stored materials. The Factories Act adds further requirements for industrial premises.

For warehouse operators seeking to meet — and exceed — regulatory expectations, the relevant benchmarks are:

NFire complies with both IS/ISO 7240 and EN54 certification, and has also been tested and validated by STQC (Standardisation Testing and Quality Certification). This dual-standard compliance provides warehouse operators with a defensible, internationally recognised safety posture.

Deploying an AIoT fire safety platform across a network of warehouses — whether owned or third-party — follows a structured approach that minimises disruption to live operations:

The warehouses powering India’s next phase of economic growth cannot afford to be the weakest link in the supply chain.

India’s warehousing and logistics sector is on a trajectory that will make it one of the largest in the world within the next decade. The fire protection systems market in India is projected to grow from USD 4.7 billion in 2025 to USD 8.6 billion by 2031 — a 10.4% CAGR driven directly by the expansion of industrial corridors and logistics parks.

But market size alone does not guarantee safety. The incidents of 2024 — from Bhiwandi to the Shiprocket warehouse — proved that conventional fire detection is no longer sufficient for the scale and complexity of modern warehousing operations. The gap between compliance on paper and genuine operational resilience is now painfully visible.

AIoT-based wireless addressable fire safety systems — platforms like NFire — close that gap. They detect threats before they become fires. They protect not just the building, but the brands, the supply chains, and the livelihoods that depend on uninterrupted operations. And they do it with the intelligence, connectivity, and compliance that India’s next generation of mega-warehouses demand.

For warehouse operators, logistics park developers, and facility managers: the question is no longer whether to upgrade. It is how quickly you can make the transition before the next fire makes the decision for you.

Explore the NFire AIoT Platform or schedule a complimentary site assessment for your facility.