India’s electric vehicle revolution is accelerating rapidly. With government initiatives like FAME II and increasing EV adoption across major cities from Mumbai to Bangalore, warehouses storing lithium-ion batteries are becoming critical infrastructure. But with this growth comes a hidden danger that most warehouse operators don’t fully understand—until it’s too late

A single failing battery can trigger a chain reaction that destroys an entire facility within minutes. Traditional fire detection systems often detect the problem only when flames are already visible. By then, the damage is inevitable

The good news? Advanced technology now exists to predict these fires hours before they happen—giving you time to prevent disaster rather than just react to it

This breakthrough comes from NFire AEGIS-Core (AIoT Advanced Early-warning General Intelligence System), an AI-powered platform that combines sophisticated sensors with machine learning to detect the invisible warning signs of thermal runaway long before flames appear

While NFire AEGIS-Core is designed for India’s exploding battery storage market—from EV manufacturing hubs in Gujarat to logistics centers in Maharashtra—the technology addresses a universal challenge. Battery warehouses in Los Angeles, Shanghai, Frankfurt, and Tokyo face identical thermal runaway risks. The physics of lithium-ion battery failure doesn’t change by geography, and neither does our solution. NFire AEGIS-Core is engineered for global deployment, protecting critical energy infrastructure wherever batteries are stored

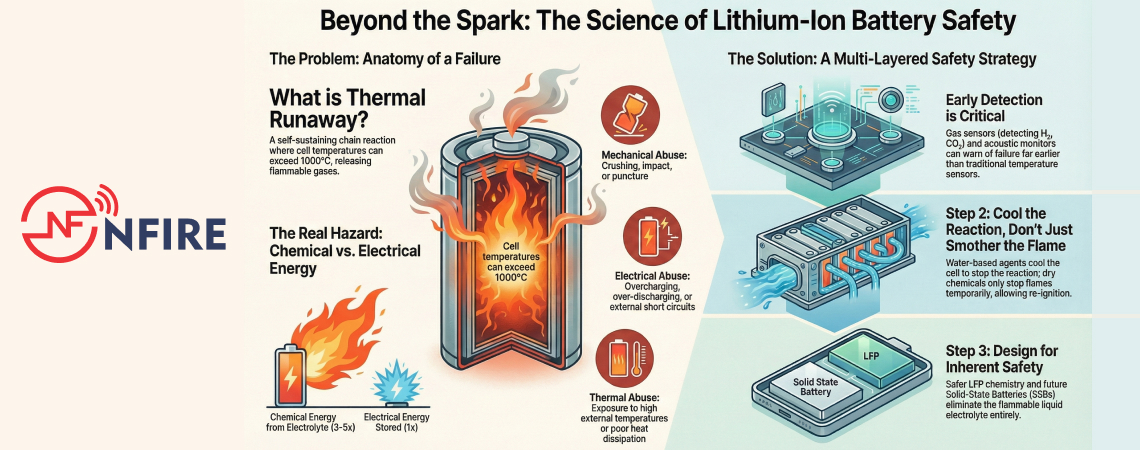

Unlike ordinary fires, lithium-ion battery fires are caused by a phenomenon called “thermal runaway”—an unstoppable chain reaction inside the battery cell itself.

Think of it like dominoes arranged in rows. Once the first domino falls, it triggers the next, and the next, creating a cascade that’s impossible to stop. In a battery warehouse, one failing cell can trigger its neighbors to fail, spreading through an entire battery pack and potentially the whole facility

The result is violent: toxic gas release, intense flames, and potential explosions as internal pressure vents. Because one battery can trigger dozens more, a single fault can escalate into a catastrophic warehouse fire.

Here’s the critical problem with conventional fire safety systems in Indian warehouses:

Standard temperature sensors and smoke detectors only trigger after the fire has already begun. By the time external sensors detect heat or smoke, the thermal runaway process inside the battery is already irreversible

Research shows that the internal fault leading to thermal runaway can develop slowly over hundreds of hours without any visible symptoms. Then, in the final stage, the battery goes from seemingly normal to catastrophic failure in mere seconds

This is the difference between passive detection (reacting after the fact) and active prevention (stopping problems before they start)—a distinction that can save your entire facility

Modern battery safety systems use a sophisticated combination of sensors that can “see” the invisible warning signs hours before a fire starts. Here’s how it works

| Sensor Technology | What It Detects | Early Warning Capability |

|---|---|---|

| Gas Sensors | Release of specific gases like carbon monoxide, hydrogen, ethylene, and methane | Detects chemical fingerprint of thermal runaway before any smoke or heat |

| Mechanical Sensors | Physical swelling, expansion, or strain on battery casing | Can provide warning up to 15 minutes earlier than temperature sensors |

| Acoustic Sensors | High-frequency sounds of gas venting or safety valve opening | Detects pressure buildup before critical temperature is reached |

| Advanced Internal Sensors | Internal temperature, stress, and chemical changes using fiber optics | Direct monitoring of conditions inside the battery |

Gas detection is particularly powerful because failing batteries release a unique chemical signature long before flames appear. The five key gases that signal thermal runaway are:

Having multiple sensors is only half the solution. The real breakthrough comes from NFire AEGIS-Core—an AIoT Advanced Early-warning General Intelligence System that analyzes millions of data points in real-time.

The power of this approach is in fusion: by combining subtle clues from gas sensors, strain gauges, acoustic monitors, and temperature readings, NFire AEGIS-Core provides warnings that are hours earlier and far more accurate than any single sensor could achieve alone.

Implementing AI-powered battery fire detection creates three layers of protection:

A comprehensive network of gas, strain, acoustic, and temperature sensors installed throughout your facility, creating a complete digital picture of battery health in real-time

AI systems analyze millions of data points, constantly comparing each battery against healthy baselines and searching for the subtle warning signs of internal faults

Instead of general alarms when it’s too late, you get specific alerts identifying exactly which battery pack needs attention—allowing your team to safely isolate and remove the problem unit before it threatens your facility

For warehouse operators, logistics companies, and EV manufacturers across India, the benefits are clear:

f you’re storing lithium-ion batteries, ask your current security provider these questions:

If the answers concern you, it’s time to consider upgrading to active monitoring technology.

Traditional fire safety systems are passive—they react after the fire has already started. By then, thermal runaway has already begun, and stopping it is nearly impossible.

Modern AI-powered systems are active—they predict fires before they happen, giving you time to prevent disaster rather than just minimize damage.

For warehouses storing lithium-ion batteries in India’s growing EV ecosystem, this difference isn’t just about technology—it’s about whether your business survives the next thermal runaway event.

Learn how NFire AEGIS-Core—Atigo Security’s AIoT Advanced Early-warning General Intelligence System—can protect your facility with advanced sensor networks and AI-powered early detection.

About the Author: Pushpendrasinh Jhala is the Founder and CEO of Atigo Enterprises Limited, the company behind the NFire brand. This article presents his research on AI-powered fire detection technology and the development of NFire AEGIS-Core for lithium-ion battery storage facilities.

Related Topics: NFire AEGIS-Core, Active Fire Monitoring, AIoT Security Systems, Warehouse Safety Solutions India, Thermal Runaway Prevention, Battery Storage Safety

To know more about NFire AIoT Wireless Fire Alarm Systems: Modern Multi-Specialty Hospitals